Mud drilling agitators

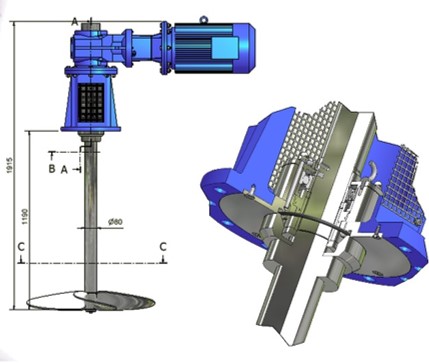

Top entry agitatorsare the largest, and probably the most expensive solution.

They are equipped with very large impellers, slow speed and the tank need to be almost full, to have a good mixing performance. Top entry agitators are difficult to fit and install with current vessel design.

Side entry agitators are smaller agitators, mostly due to the shorter agitator shaft. They are mounted on the side of the tank and are always in contact with the drilling mud. It is very important that these agitators are equipped with a mechanical seal, and with a system for changing the seal, in case of a leak, although rarely seen. As the motor of the device is placed outside the tank operation and maintenance is hassle free and uncomplicated.

APPLICATIONS:

- Agitators for homogenizing the drilling muds

Know More..

Agitators

IKA agitators are ideal for acceleration of solution processes and syntheses, temperature exchanges within a medium as well as the mixing of easily mixable liquids and solids. The agitator’s primary application is the processing of flowable mixtures in a low to medium viscosity range. Agitators can be optionally equipped with a fast propeller, an axial turbine, a stirring disk, a toothed disk, an IBC cup stirrer, or a slow and powerful anchor stirrer.

The IKA ROTOTRON® jet stream agitator stands out due to an extremely strong axial conveying effect. Even when it comes to less-than-optimal vessel dimensions and shapes, the jet stream agitator ensures a very intensive recirculation of the mixture while using relatively low energy input.

APPLICATIONS:

- Agitators are ideal for acceleration of solution processes and syntheses, temperature exchanges within a medium as well as the mixing of easily mixable liquids and solids

Know More..